Our manufacturing processes

Technical and human expertise to ensure your success

Our ISO 8/7 clean rooms house our state-of-the-art equipment to ensure the highest levels of performance, safety, hygiene and productivity. In our modern modular facilities, we have industrial expertise in a wide range of processes and draw on our programme management and qualification teams to contribute to your success.

Plastic transformation

We offer single and dual material plastic injection moulding of high precision parts for standard products or bespoke solutions in an ISO 8 – 7 environment. We also offer extrusion blow moulding services for PE pillboxes and PET bottles.

Automation

We guarantee the quality, reliability and repeatability of all our products by automating our production processes so that customers receive a finished product.

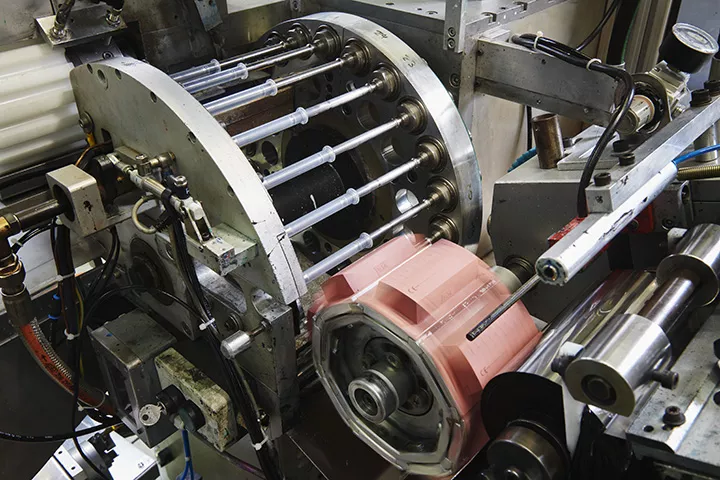

Marking

We offer a range of marking processes to suit every need: rotary pad printing, flat pad printing, screen printing, In-Mould Labelling (IML), hot stamping, engraving, etc.

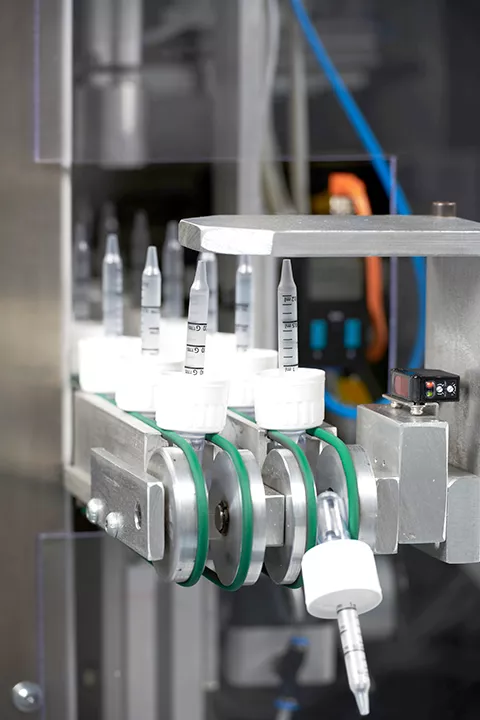

Assembly

We make life easier for our customers by optimising their supply chain by assembling finished products in our factories.